Servo Motors

Servo Motors

Goals

- Discuss servos

- Difference between servos and DC motors

- Implement a servos

- Combine DC motors and servos

Servo

- Short for “servomechanism”

- A servomotor is a type of servomechanism

- Uses feedback mechanism to precisely control the position or effect of a mechanical device

Servomotor Applications

- Hobby servos typically control angles

- Some servos are continuous and are essentially precisely controlled DC motors with a feedback mechanism

- Service range of typical servos are between 0 and 180 degrees

- However, rotating to the full range (0 and 180) can damage so often we use a smaller range such as 15-165

Inside Servo Motors

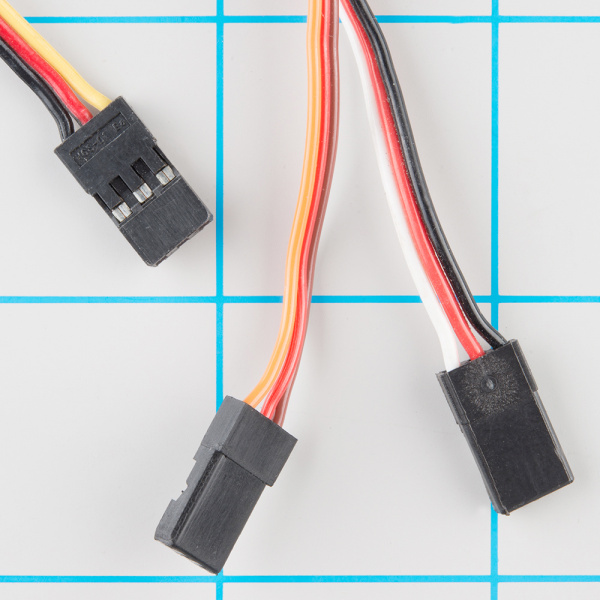

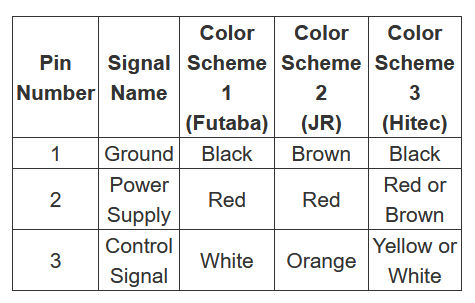

Quick Note on Wire Colors

- The wiring colors vary with different servos so look carefully at your documentation

- Many servos will require 5V not 3.3V so use

VUSB

Wiring Diagram

Servo Class

-

The

servoclass is already part of the Particle OS, meaning we don’t need any special libraries to run it -

The

servoclass has a constructor for a Servo object and methods to interact with the servo

Servo Code

-

Create the Servo object

-

Attach the Servo object to a pin

-

Write to the Servo object

Servo Code - Creating the Servo Object

const int SERVO_PIN = D2;

//Create the servo object

Servo servoObj;

void setup(){

//attach the servo object to the servo pin

servoObj.attach(SERVO_PIN);

}

Servo Code - Turning the Physical Servo

void loop(){

servoObj.write(15); //write the servo to position 15 degrees

delay(1000); //wait one second

servoObj.write(90); //write the servo to position 90 degrees

delay(1000);

servoObj.write(165); //write servo to position 165 degrees

delay(1000);

}

Important Note about Servo Class

- The Photon 2 uses a single internal timer to contol all PWM pins. These means all the pins share the same frequency but can have different duty cycles

- The

Servoclass uses 50 Hz, but by defaultanalogWrite()uses 500 Hz. - This means that if you are combining

servo.write()with DC motors or LEDs that useanalogWrite(), the servo won’t work properly because the Photon 2 will switch to the wrong frequency - The solution is to use specify

analogWriteto use 50 HzanalogWrite(PIN, VALUE, 50);

Servo Limitations

- Small hobby servos usually have a small plastic tab that keeps the armature from rotating past a certain point

- Rotating beyond this point usually breaks the small plastic tab

- This creates a continuous servo

- Important

- Our servos require 5v so they will not work with a LiPo battery (3.7v).

- If you want to use a servo with a LiPo battery, see these instructions

Controlling a Servo

- We can use a potentiometer to control a servo’s positioning

-

Potentiometers have values 0 – 4095

-

Have to scale that value to be 15 – 165

- Use the map() function

map() Function

map(value, fromLow, fromHigh, toLow, toHigh)

// value – value we want to convert

// fromLow – input low value

// fromHigh – input high value

// toLow – output low value

// toHigh – output high value

map() Function

int potVal = analogRead(POTPIN);

int angleVal = map(potVal, 0, 4095, 15, 165);

Fixing Servo Jittering

- In some cases, the servo may start to make noise, stutter, or become hot when not it use

- This can be due to a variety of factors such as unstable current supply or interrupts in the Photon 2 execution

- IF this happens, one simple solution is to

attachbefore using the servo, and thendetachafter

Fixing Servo Jittering - Code

const int SERVO_PIN = D2;

Servo servoObj;

void setup(){ /*no attach code */ }

}

void loop(){

servoObj.attach(SERVO_PIN);

servoObj.write(15); //write the servo to position 15 degrees

delay(1000); //wait one second

servoObj.write(90); //write the servo to position 90 degrees

servoObj.detach();

}

Reminder: Photon 2 PWM Pins

- Only certain pins support PWM

D1(SCLorA4)A2A5MISO(D16)MOSI(D15)

Exercise

- Connect a servo and write code to sweep through the entire range of value (Remember: use

15and165instead of0and180to avoid damaging servo) - Connect a potentiometer to control the position of the servo

- Using tape, connect your DC motor (with fan blade) to the servo. With the fan spinning, use the pot to control the position of the fan

- Now use the pot to control the speed of the fan while the servo rotates continuosly

Wiring

Motor Controller Wiring Guide

| Motor Controller | Photon 2 | DC Motor |

|---|---|---|

| PWMA | A5 | - |

| AI2 | D4 | - |

| AI1 | D3 | - |

| AO1 | - | Motor wire (either) |

| AO2 | - | Motor wire (either) |

| VCC | 3v3 | - |

| GND | GND | - |

| VM | 3v3 | - |

| STBY | 3v3 | - |