DC Motors

DC Motors

Goals

-

Discuss the different types of motors used in small electronic devices

-

Introduce DC motors

-

DC motor power considerations

-

DC motor applications

DC Motor Applications

- Hobby motors

- Small electronics

- Low-torque applications

- Large DC motors

- Electric scooters

- High-torque applications

- Motors can also generate electricity (generators / alternators)

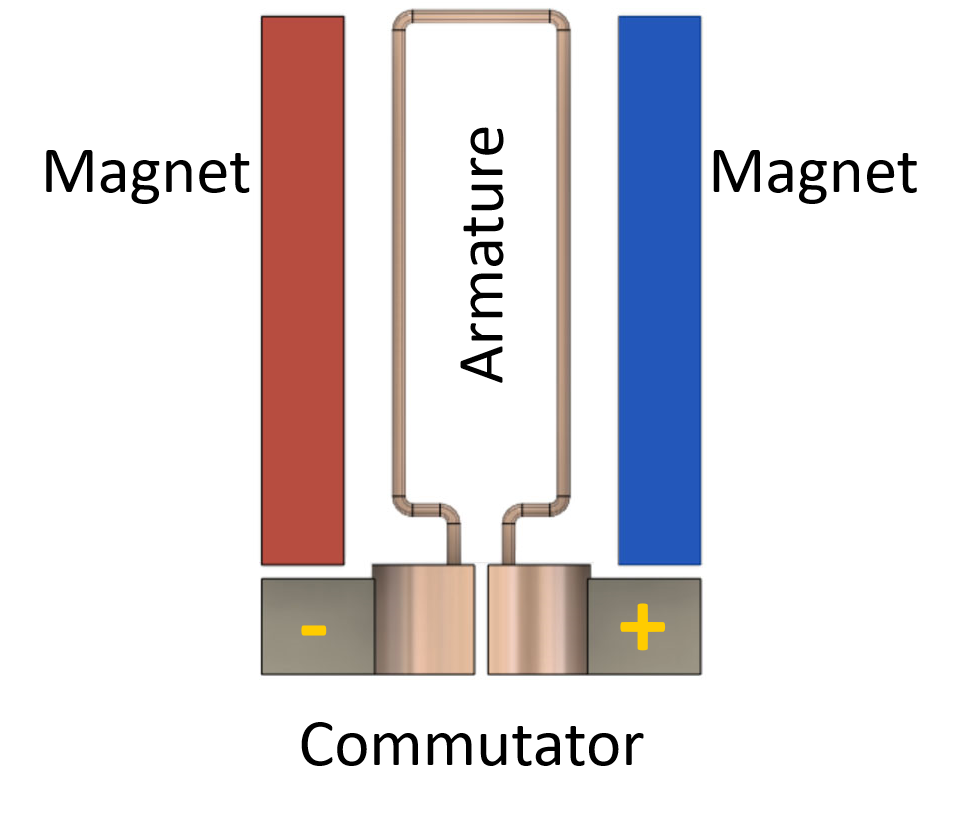

How Do Brushed Motors Work?

- Electromagnetism!

- VERY brief physics aside

Electromagnetism

-

The guiding principle behind electric motors is the Lorentz Force

- Electrical current in a magnetic field produces a physical force

- Force direction is given by the “right-hand rule”

- Current direction along your index

- Magnetic field along your middle

- Force direction is along your thumb

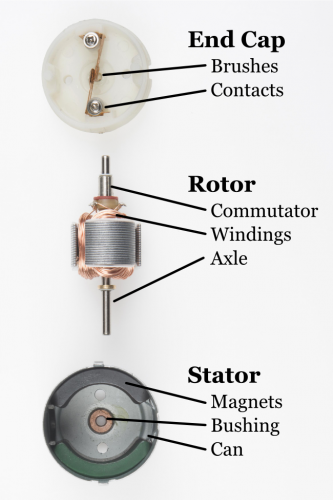

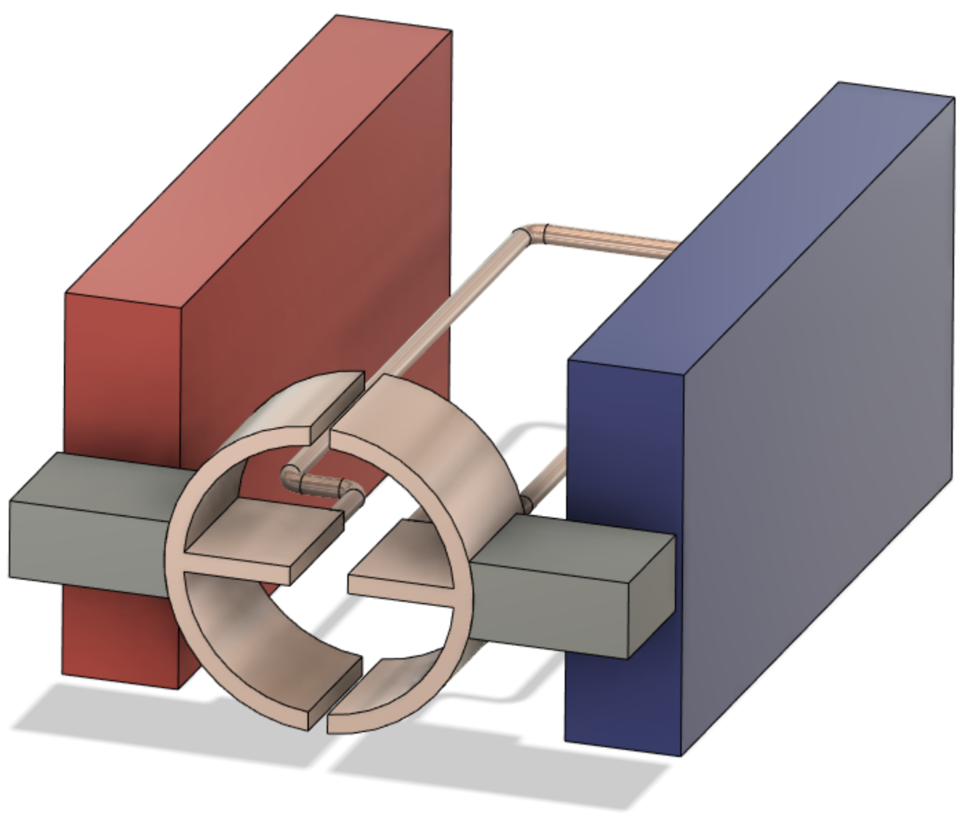

Three Main Parts of DC Motor

- Stator magnets (stationary)

- Armature / Windings (rotating wire)

- Commutator (supplies current to armature)

Inside Simple DC Motor

DC Motor Construction

Illustration

DC Motor Types

| Brushed | Brushless (synchronous or electronically commutated motor) |

|---|---|

| Physical contact points in the commutator to switch current direction | Inverter to electrically switches the DC power supply to AC power supply |

| Pro: Relatively inexpensive | Pro: Less wear on moving parts |

| Con: Parts wear out over time | Con: More expensive |

Exercise

- Attach fan blade to motor

- Connect red wire on motor to 3v3; connect black wire to ground

- What happens?

- Reverse the wires

- What happens?

- Was the speed the same in either case?

Motors

- Spin is controlled by current direction

- If direction is reversed, the motor spins in the opposite direction

- It is not practical to have to reverse the wires to change motor direction

- Also, we have no way to control speed

Motor Controller

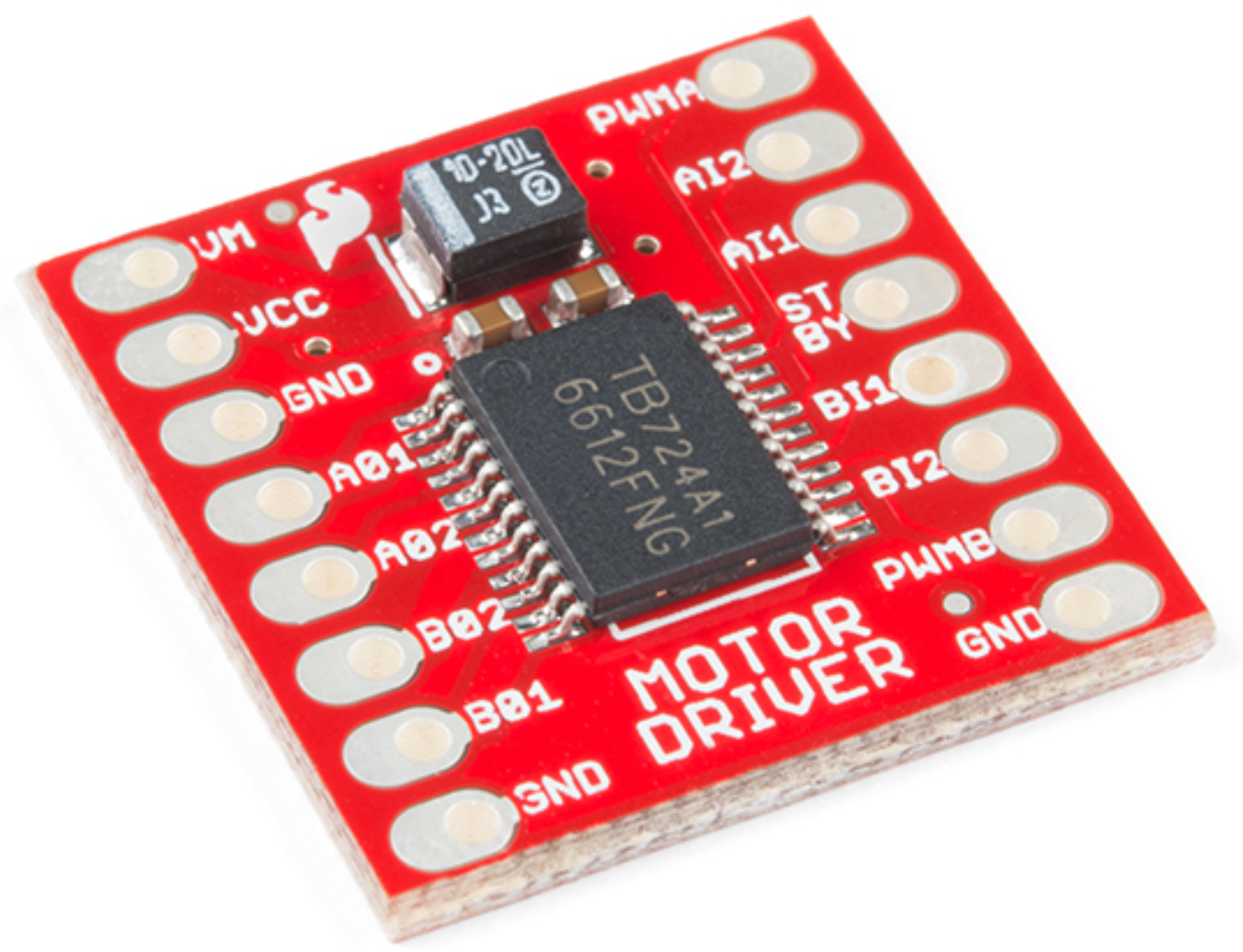

Motor Driver

- Motor (motor controller) provide greater control over motors

- Motor drivers don’t give a (+) or (-) connection

- Just have an IN1 or IN2 because we can change polarity

- Motor drivers also provide circuit protection

- Motor drivers can control two different motors independently

Motor Controller Wiring Guide

| Motor Controller | Explanation |

|---|---|

| PWMA | Motor A speed (PWM) |

| AI1, AI2 | Motor A direction control (connect to Photon 2) |

| AO1, AO2 | Motor A output (connect to motor) |

| PWMB, BI1, BI2, BO1, BO2 | Controls for motor B |

| VCC | Power for chip (3v3) |

| VM | Power for motors (3v3, or higher for powerful motors) |

| STBY | Enable motor (3v3) |

| GND | Ground |

</span>

Controlling the Motor Direction

- Setting the direction is done by changing the two input pins to HIGH and LOW separatel

- Ex:

AI1 = HIGHandAI2 = LOWis one direction - Ex:

AI1 = LOWandAI2 = HIGHis other direction

- Ex:

- Setting them both to LOW means stopping the motor

- Setting them both to HIGH can damage the motor

Controlling the Motor Speed

- The PWM method of controlling motor speed operates on this range: [0-255]

- Typically the PWM must be somewhat greater than 0 before it starts to spin

- Reminder: only certain pins support PWM

D1(SCLorA4)A2A5MISO(D16)MOSI(D15)

Wiring Diagram

Wiring Guide

| Motor Controller | Photon 2 |

|---|---|

| PWMA | A5 |

| AI2 | D4 |

| AI1 | D3 |

| AO1 | Motor wire (either) |

| AO2 | Motor wire (either) |

| VCC | 3v3 |

| GND | GND |

| VM | 3v3 |

| STBY | 3v3 |

Exercise

- Attach the fan blade to the DC motor

- The theoretical PWM values are 0 to 255. Write a sketch to determine the min and max values.

- Write a sketch that powers up the fan from the practical minimum (the value we established in the previous exercise) to the maximum

- There should be a ramp up in speed, getting progressively faster until it maxes out